Types Of Calendering

Types Of Calendering - The main calendering methods for various paper and board grades. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. A process of passing cloth between rollers (or “calendars”), usually under carefully controlled heat and pressure, to produce a variety of surface. Web the different calender types. Web valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers. When carried out on a paper machine, it is called. There are four classifications of thermoformin. There are various calender types, including embossing calenders, friction. Web this simultaneous action is called calendering. Calendering is a finishing process used on cloth and fabrics.

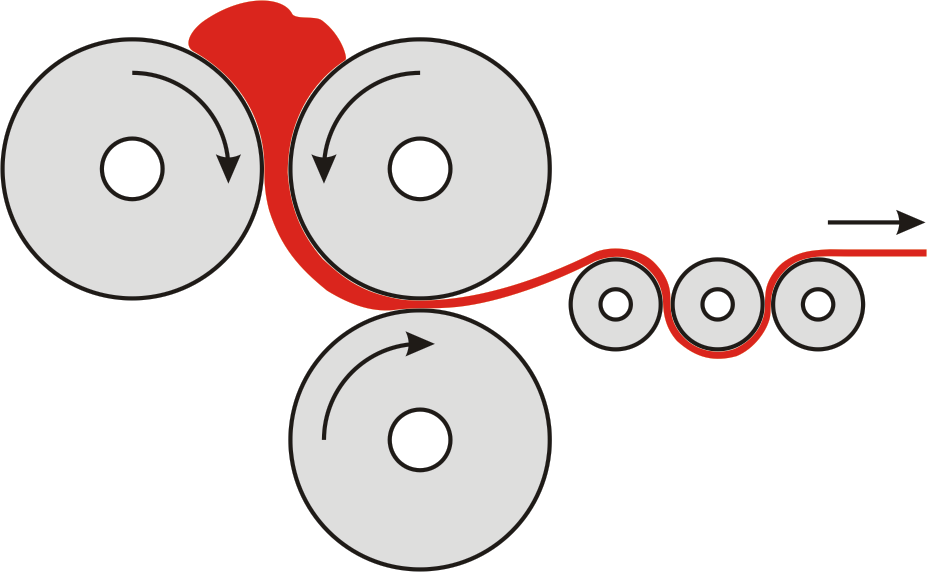

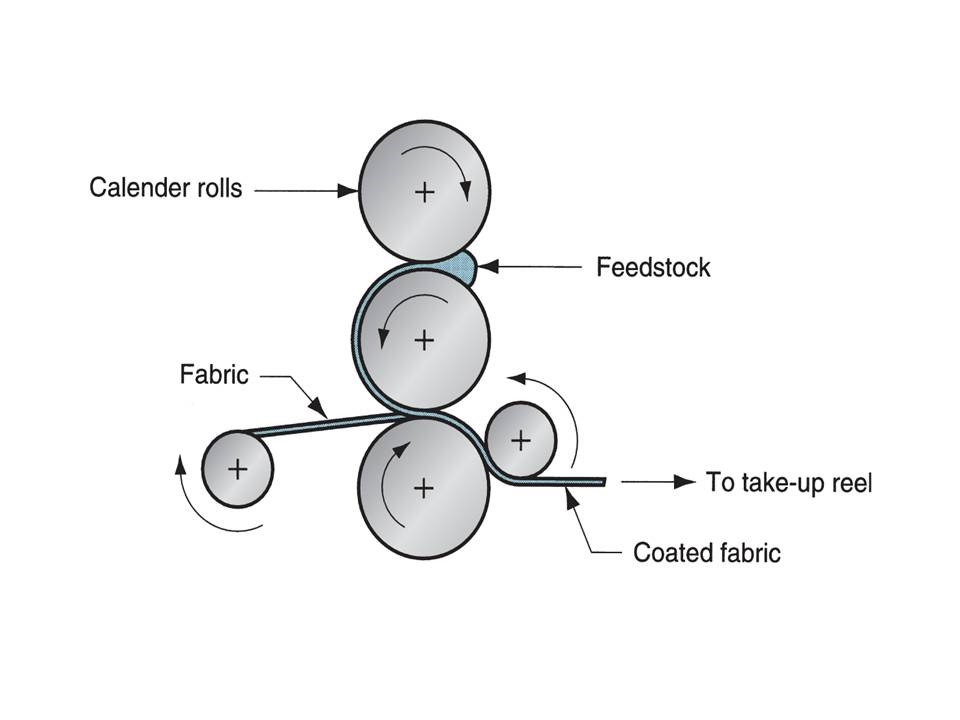

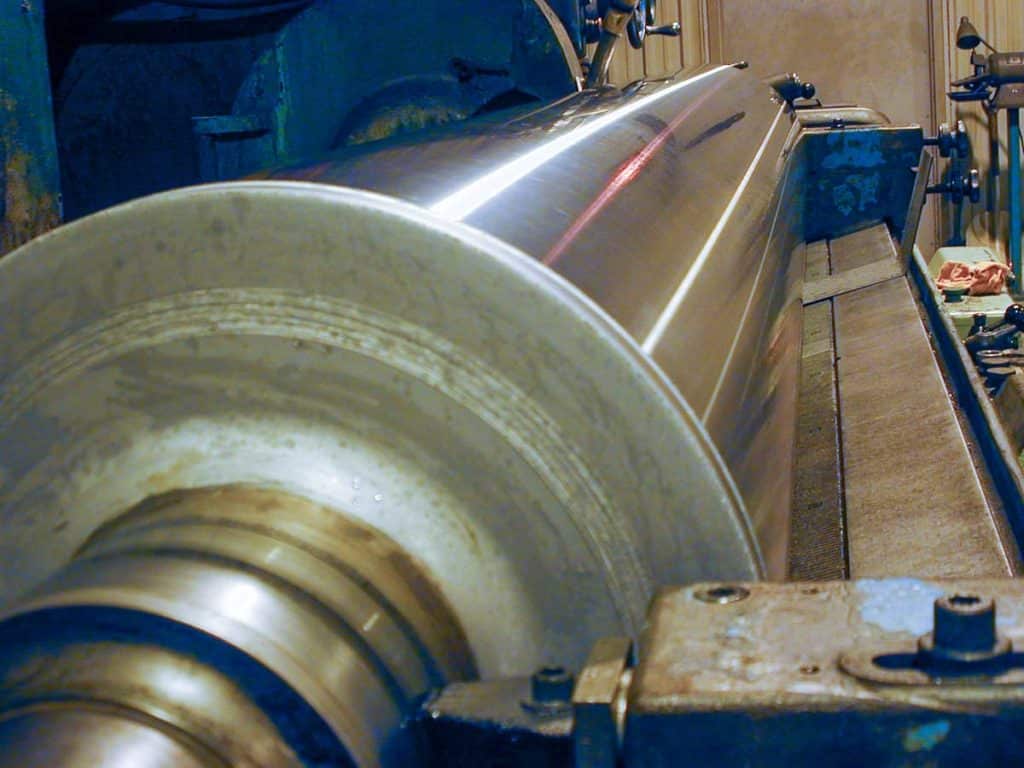

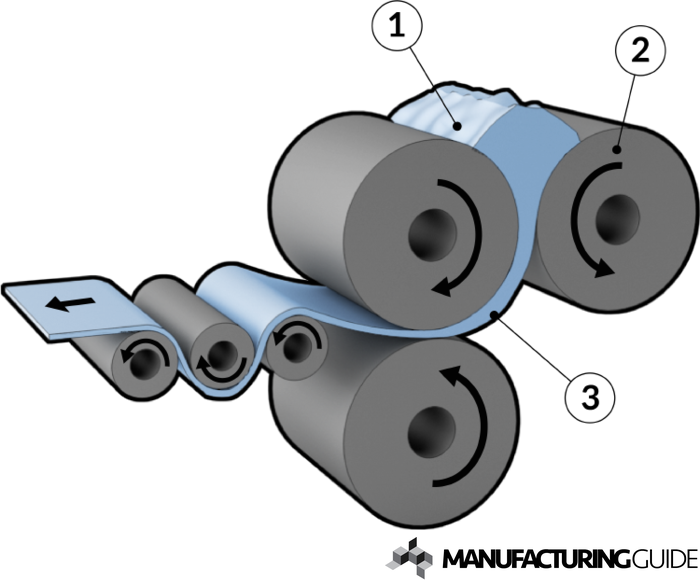

Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. Factors that govern the advantages and disadvantages of each process can. Web calendering is a type of mechanical levelling and segmenting process for ‘finishing’ fabrics or webs to produce a special effect, namely flattening, lustre, compacting, glazing,. Soft nip or hard nip calendering, with single or multiple nips, whether calendering on one or both paper sides. When carried out on a paper machine, it is called. A calender is employed, usually to smooth, coat, or thin a material. Web valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers. The main calendering methods for various paper and board grades. Web calendering or extrusion film and sheet can, in principle, be made by calendering or by extrusion.

Swizzing calendars usually consist of seven to ten bowls. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web the different calender types. Web this simultaneous action is called calendering. Web common types of calendering machine used in the textile industry include: Web which types of calendering are used in textiles? Factors that govern the advantages and disadvantages of each process can. Web voith offers calendering solutions for every requirement: Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. There are four classifications of thermoformin.

6 Types of Calendering Process in Textile ! Textile Property

Swizzing calendars usually consist of seven to ten bowls. Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. A calender is employed, usually to smooth, coat, or thin a material. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. With textiles,.

6 Types Of Calendering Process In Textile Textile Property

Web this simultaneous action is called calendering. With textiles, fabric is passed under rollers at high temperatures and pressures. There are various calender types, including embossing calenders, friction. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. Web the different calender types.

6 Types Of Calendering Process In Textile Textile Property

Swizzing calendars usually consist of seven to ten bowls. In hot calendering, fabric passes. Web common types of calendering machine used in the textile industry include: Soft nip or hard nip calendering, with single or multiple nips, whether calendering on one or both paper sides. Web this simultaneous action is called calendering.

10 Facts About Calendering in Textile! Textile Property

There are various calender types, including embossing calenders, friction. When carried out on a paper machine, it is called. Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Web voith offers calendering solutions for every requirement: There are four classifications of thermoformin.

Nonwoven calendering performs crucial steps in manufacturing

Web valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. It converts the raw rubber material into a. Swizzing calendars usually consist of seven to ten bowls. A process of passing.

Types Of Calendering

Web calendering can be classified into various types based on the desired effect and the characteristics of the fabric: Swizzing calendars usually consist of seven to ten bowls. Soft nip or hard nip calendering, with single or multiple nips, whether calendering on one or both paper sides. Calendering, shown in figure 2, is a unit operation which compresses the paper.

Calendering Find suppliers, processes & material

Textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering,. A process of passing cloth between rollers (or “calendars”), usually under carefully controlled heat and pressure, to produce a variety of surface. In hot calendering, fabric passes. It converts the raw rubber material into a. Calendering is used on fabrics such as moire to produce its watered effect and.

6 Types of Calendering Process in Textile ! Textile Property

Web the type of calender used depends on the type of cloth to be run and the relevant desired effect. Web calendering or extrusion film and sheet can, in principle, be made by calendering or by extrusion. When carried out on a paper machine, it is called. Web the different calender types. Web voith offers calendering solutions for every requirement:

Calendering Alpha

With textiles, fabric is passed under rollers at high temperatures and pressures. It converts the raw rubber material into a. Web calendering can be classified into various types based on the desired effect and the characteristics of the fabric: Web which types of calendering are used in textiles? Web common types of calendering machine used in the textile industry include:

Calender Wikipedia

Web valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers. It converts the raw rubber material into a. Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Another area of application is pre. Web this simultaneous action is called calendering.

With Textiles, Fabric Is Passed Under Rollers At High Temperatures And Pressures.

Web calendering or extrusion film and sheet can, in principle, be made by calendering or by extrusion. Web which types of calendering are used in textiles? It converts the raw rubber material into a. There are various calender types, including embossing calenders, friction.

Calendering Is Used On Fabrics Such As Moire To Produce Its Watered Effect And Also On Cambric And Some Types Of Sateens.

Web the different calender types. Web there are several different types of calendering, each with its own unique characteristics and applications, including hot calendering, emboss calendering, and compacting. Web common types of calendering machine used in the textile industry include: The main calendering methods for various paper and board grades.

Web Calendering Can Be Classified Into Various Types Based On The Desired Effect And The Characteristics Of The Fabric:

Web voith offers calendering solutions for every requirement: Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. Web the types of calendaring machines getting used in the industry are given below: Web valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers.

In Hot Calendering, Fabric Passes.

Calendering is a finishing process used on cloth and fabrics. A process of passing cloth between rollers (or “calendars”), usually under carefully controlled heat and pressure, to produce a variety of surface. Calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Soft nip or hard nip calendering, with single or multiple nips, whether calendering on one or both paper sides.