Seaming In Sheet Metal

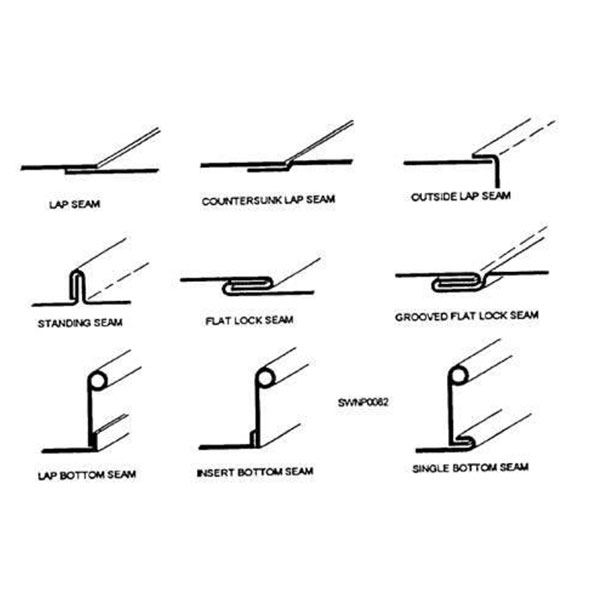

Seaming In Sheet Metal - Some common design choices for sheet metal joints are based on usage and seam characteristics. Web seams run parallel to the air flow, while joints are perpendicular to the air flow. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. The resulting shape may even form a seal that isolates one side of the sheets from the other. Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Web from the outside, you may only see a seam, bump, or nothing at all. Web a seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts.

Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Some common design choices for sheet metal joints are based on usage and seam characteristics. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web from the outside, you may only see a seam, bump, or nothing at all. Web seams run parallel to the air flow, while joints are perpendicular to the air flow. The resulting shape may even form a seal that isolates one side of the sheets from the other. Web a seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts.

Web a seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web seams run parallel to the air flow, while joints are perpendicular to the air flow. Web from the outside, you may only see a seam, bump, or nothing at all. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The resulting shape may even form a seal that isolates one side of the sheets from the other. Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Some common design choices for sheet metal joints are based on usage and seam characteristics.

D'source Hemming and Seaming Sheet Metal Joinery D'Source Digital

Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web.

D'source Hemming and Seaming Sheet Metal Joinery D'Source Digital

The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Some common design choices for sheet metal joints are based on usage and seam characteristics. Web from the outside, you may only see a seam, bump, or nothing at all. Web a seam is used to connect two.

Sheet Metal Seams MEP Academy

The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Web seams run parallel to the air flow, while joints are perpendicular to the air flow. Hemming is.

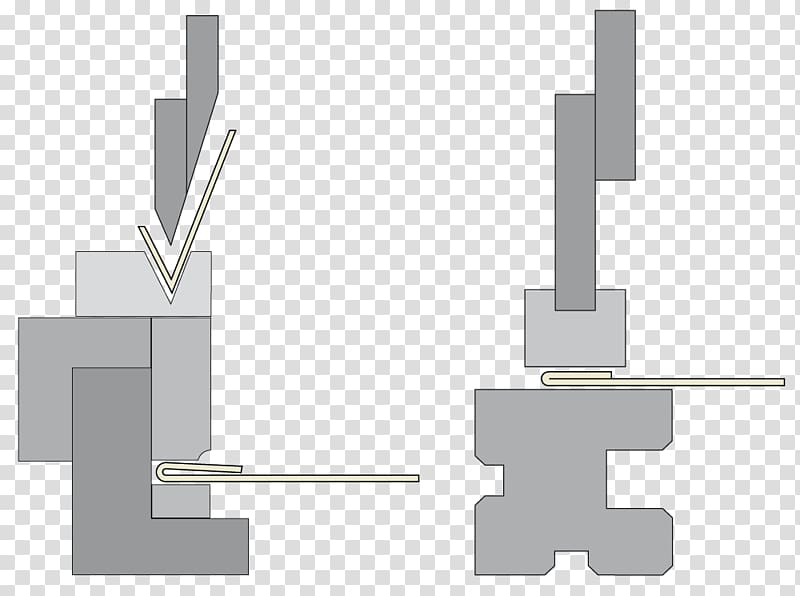

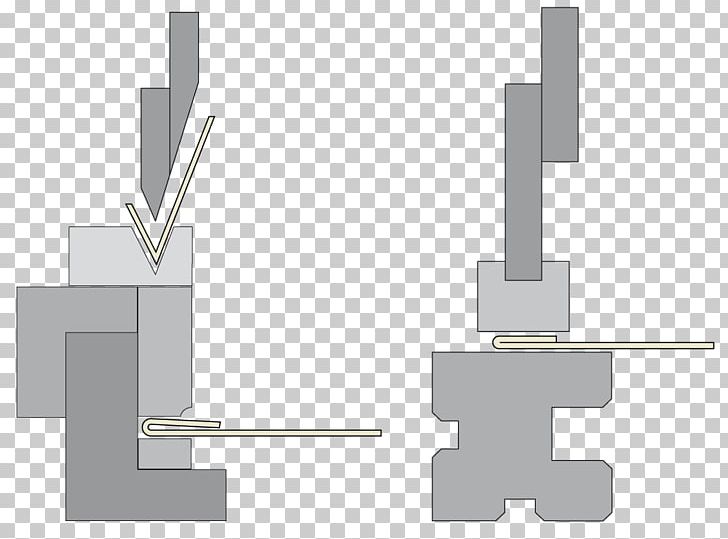

Bending Press brake Hemming and seaming Sheet metal, others transparent

Some common design choices for sheet metal joints are based on usage and seam characteristics. The resulting shape may even form a seal that isolates one side of the sheets from the other. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web a seam is used.

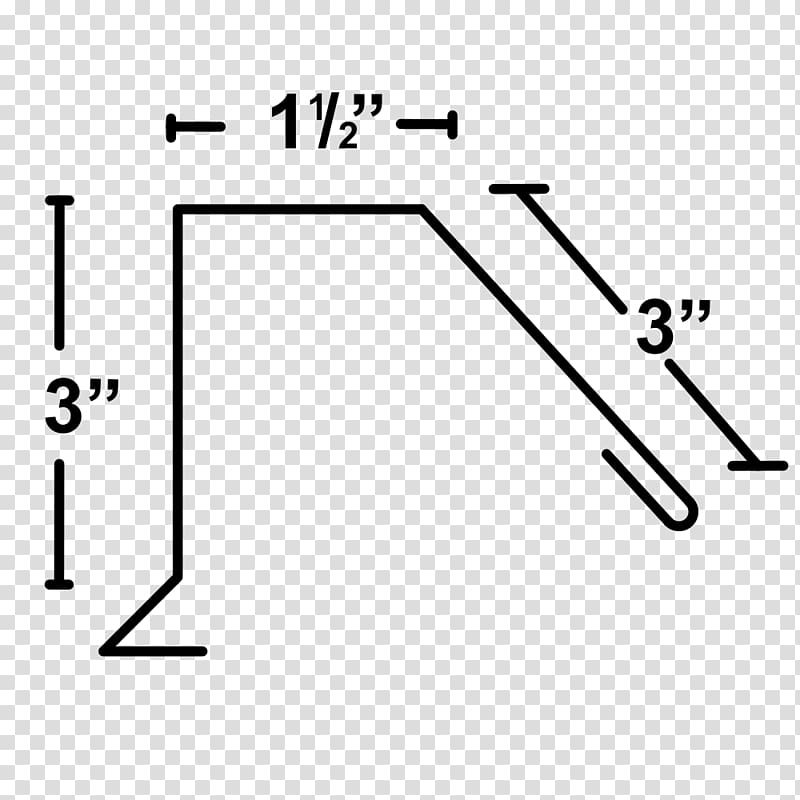

Bannister Custom Exteriors, Roofing & Siding Hemming and seaming Sheet

Web from the outside, you may only see a seam, bump, or nothing at all. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Some common design choices for sheet metal joints are based on usage and seam characteristics. Web a seam is used to connect two.

Bending Press Brake Hemming And Seaming Sheet Metal PNG, Clipart, Amada

Some common design choices for sheet metal joints are based on usage and seam characteristics. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Web seams run parallel to the.

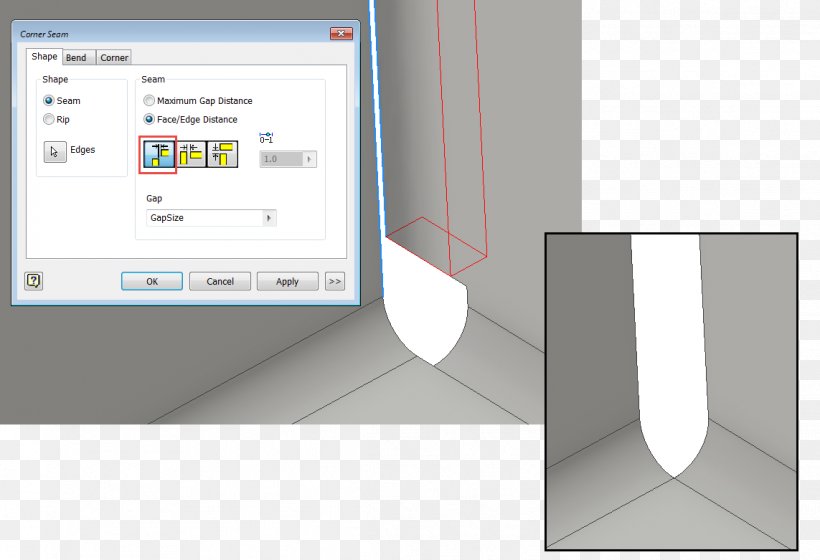

Autodesk Inventor Hemming And Seaming Sheet Metal Computer Software

Web seams run parallel to the air flow, while joints are perpendicular to the air flow. Hemming is the process in which the edge is rolled flush to itself, while a seam joins. Web from the outside, you may only see a seam, bump, or nothing at all. Web hemming and seaming are two similar metalworking processes in which a.

INCH Technical English pictorial seams & hems (sheet metal)

The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. Web a seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over.

Standing Seam Aluminum Metal Roofing Sheets Buy standing seam metal

Web seams run parallel to the air flow, while joints are perpendicular to the air flow. Some common design choices for sheet metal joints are based on usage and seam characteristics. Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The resulting shape may even form a seal that.

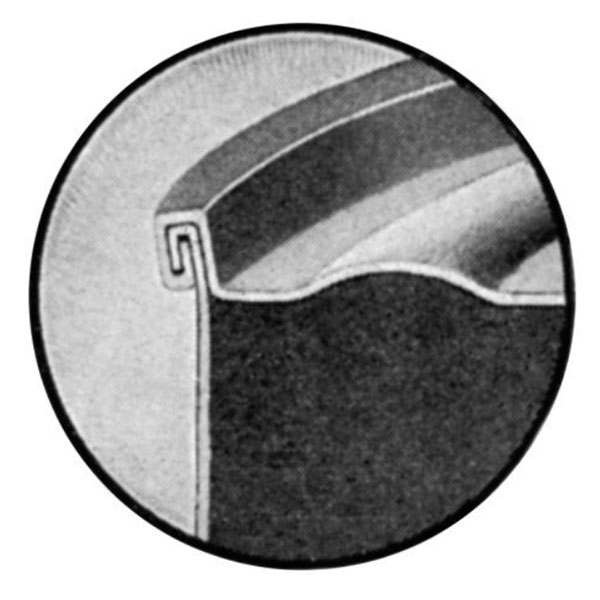

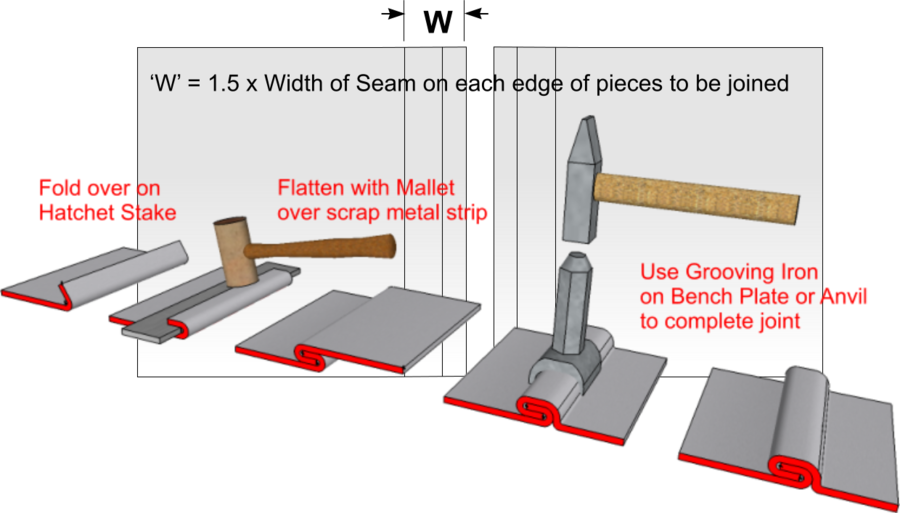

Grooved Seam Joint DT Online

Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Web from the outside, you may only see a seam, bump, or nothing at all. Some common design choices for sheet metal joints are based on usage and seam characteristics. The resulting shape may even form a seal that isolates.

Some Common Design Choices For Sheet Metal Joints Are Based On Usage And Seam Characteristics.

Web hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. The seams hold together the duct or section of a single fitting as opposed to a joint that connects two separate pieces. The resulting shape may even form a seal that isolates one side of the sheets from the other. Hemming is the process in which the edge is rolled flush to itself, while a seam joins.

Web Seams Run Parallel To The Air Flow, While Joints Are Perpendicular To The Air Flow.

Web a seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. Web from the outside, you may only see a seam, bump, or nothing at all.