How To Vacuum Form

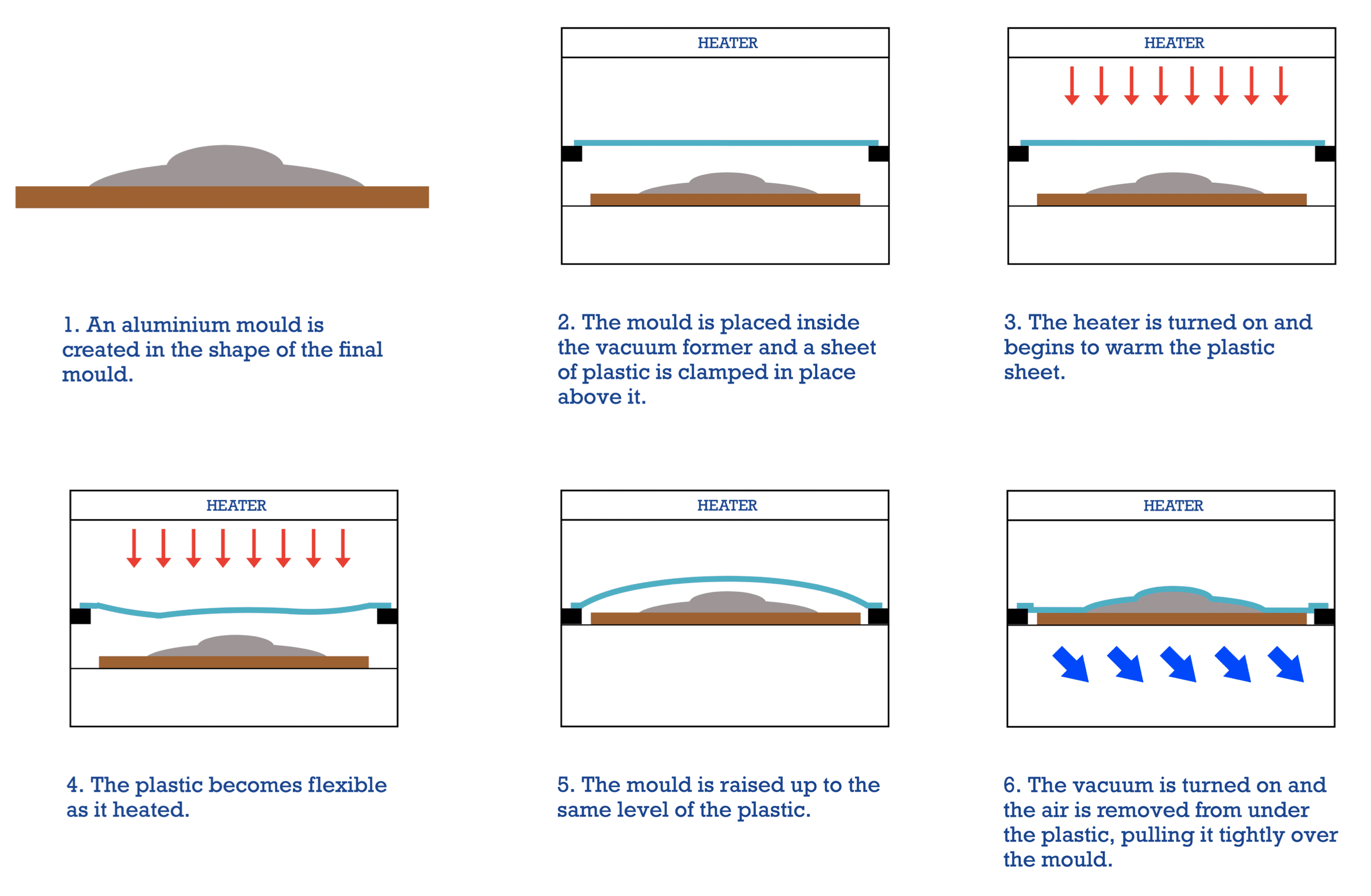

How To Vacuum Form - With vacuum forming, a vacuum pump sucks the plastic into the mould. Stick to the vacuuming guidelines below to learn the best way to vacuum. After the formed plastic cools and hardens, it’s removed from the mold and trimmed. It's getting hot in here. A sheet of plastic is placed in an open frame and clamped into place. I set up my heaters, turn them. The idea is to try to cover up little holes in the foam, while giving it a nice, hard,. By danger is my middle name in workshop science. Place the thermoform plastic in your kitchen oven and. Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould.

With vacuum forming, a vacuum pump sucks the plastic into the mould. Web this short film explains the process of vacuum forming, which is an easy way to make hollow plastic mouldings which can be used in a wide variety of rmt design projects. Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. The sheet is set on a mold. A sheet of thermoplastic material is heated in an oven. Web currently, the two main approaches to thermoforming are vacuum forming and pressure forming. By danger is my middle name in workshop science. A sheet of plastic is placed in an open frame and clamped into place. Web how to vacuum form foam (reusing the same master, many times) step 1: The idea is to try to cover up little holes in the foam, while giving it a nice, hard,.

The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Web currently, the two main approaches to thermoforming are vacuum forming and pressure forming. Build your own vacuum former using these diy vacuum former projects! Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. It's getting hot in here. This process is used to create many of the products in your home such as plastic containers, tubs,. With vacuum forming, a vacuum pump sucks the plastic into the mould. Web to vacuum form a plastic product: I set up my heaters, turn them. A sheet of thermoplastic material is heated in an oven.

How to build a vacuum forming mold to make your own plastic parts

Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. Web to vacuum form a plastic product: Place your model on top of the vacuum formers perforated aluminum platen. The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Vacuum forming.

Vacuum Forming Company API Heavy Gauge Thermoforming

I set up my heaters, turn them. After the formed plastic cools and hardens, it’s removed from the mold and trimmed. The idea is to try to cover up little holes in the foam, while giving it a nice, hard,. A sheet of thermoplastic material is heated in an oven. The plastic sheet is softened using a heat source until.

Formech FP1 Vacuum Forming Machine Refurbished Manual Cycle YouTube

Web this short film explains the process of vacuum forming, which is an easy way to make hollow plastic mouldings which can be used in a wide variety of rmt design projects. The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Build your own vacuum former using these diy vacuum former.

Building a vacuum forming machine

Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. A vacuum pulls air out of the mold, pulling the sheet against the mold to shape it. The sheet is set on a mold. Place the thermoform plastic in your kitchen oven and. The idea is to try to.

Vacuum Forming Services Plastic Vacuum Forming, Thermoplastic

With vacuum forming, a vacuum pump sucks the plastic into the mould. Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. A vacuum pulls air out of the mold, pulling the sheet against the mold to shape it. Place your model on top of the vacuum formers perforated.

How To Vacuum Form Plastic Mouldings Northern

The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. After the formed plastic cools and hardens, it’s removed from the mold and trimmed. Stick to the vacuuming guidelines below to learn the best way to vacuum. A sheet of plastic is placed in an open frame and clamped into place. A.

Vacuum Forming Company London Vacuum Formed Parts

Stick to the vacuuming guidelines below to learn the best way to vacuum. Vacuum forming is a manufacturing process by which a sheet of plastic is heated and pressed over a form to create a part. Web this short film explains the process of vacuum forming, which is an easy way to make hollow plastic mouldings which can be used.

What is Vacuum Forming ? YouTube

It's getting hot in here. Web currently, the two main approaches to thermoforming are vacuum forming and pressure forming. Build your own vacuum former using these diy vacuum former projects! I set up my heaters, turn them. A sheet of plastic is placed in an open frame and clamped into place.

Vacuum Forming YouTube

Web how to vacuum form foam (reusing the same master, many times) step 1: Stick to the vacuuming guidelines below to learn the best way to vacuum. The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Build your own vacuum former using these diy vacuum former projects! A sheet of thermoplastic.

How To Vacuum Form in 3 Easy Steps YouTube

The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould. Place your model on top of the vacuum formers perforated aluminum platen. A sheet of plastic is placed in an open.

Place The Thermoform Plastic In Your Kitchen Oven And.

After the formed plastic cools and hardens, it’s removed from the mold and trimmed. Web this short film explains the process of vacuum forming, which is an easy way to make hollow plastic mouldings which can be used in a wide variety of rmt design projects. This process is used to create many of the products in your home such as plastic containers, tubs,. A sheet of thermoplastic material is heated in an oven.

It's Getting Hot In Here.

I set up my heaters, turn them. A sheet of plastic is placed in an open frame and clamped into place. Make prototypes in your own home! Web currently, the two main approaches to thermoforming are vacuum forming and pressure forming.

Vacuum Forming Is A Manufacturing Process By Which A Sheet Of Plastic Is Heated And Pressed Over A Form To Create A Part.

The plastic sheet is softened using a heat source until it reaches the appropriate forming temperature and becomes. Stick to the vacuuming guidelines below to learn the best way to vacuum. A vacuum pulls air out of the mold, pulling the sheet against the mold to shape it. Web how to vacuum form foam (reusing the same master, many times) step 1:

Place Your Model On Top Of The Vacuum Formers Perforated Aluminum Platen.

The idea is to try to cover up little holes in the foam, while giving it a nice, hard,. Web to vacuum form a plastic product: By danger is my middle name in workshop science. Vacuum forming versus pressure forming vacuum forming and pressure forming take the opposite approach to getting the plastic into the mould.