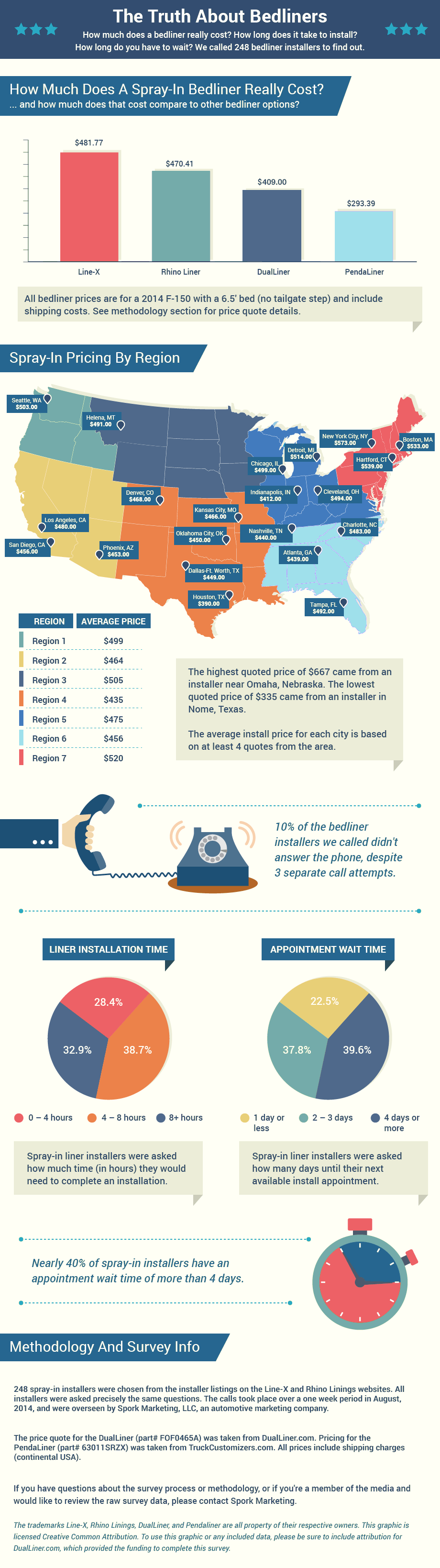

Form Liner Cost

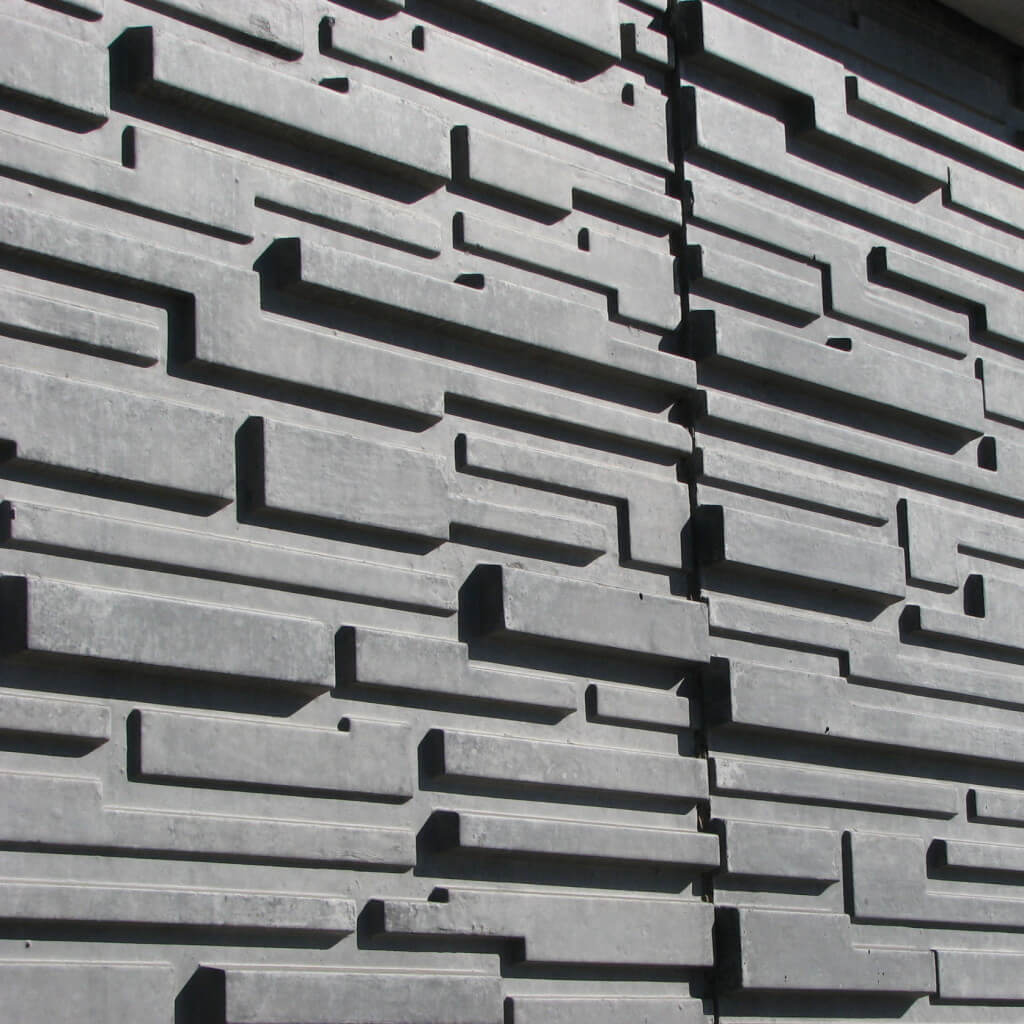

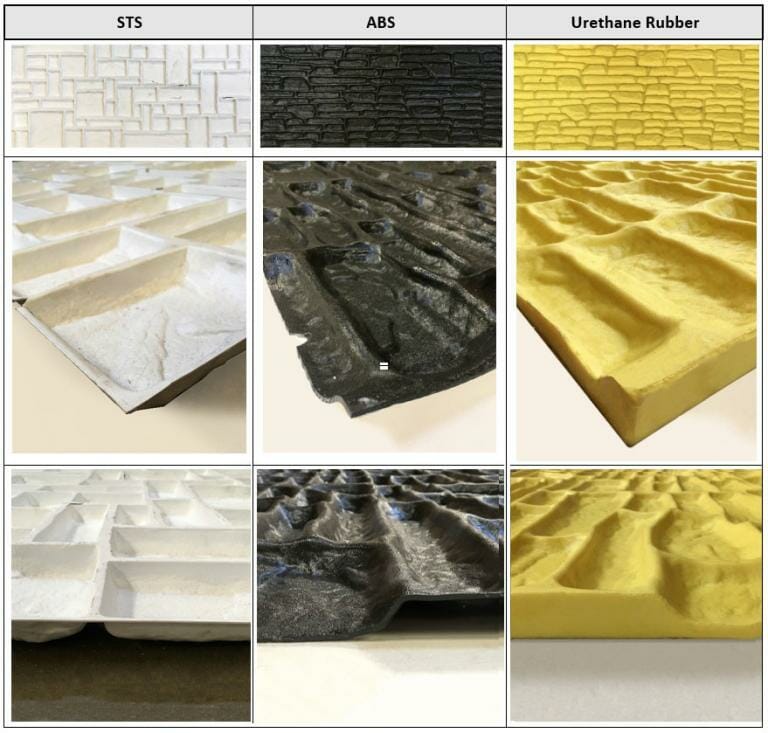

Form Liner Cost - Ensure the correct side of the liner is facing formwork (sika formliners have a tag indicating the formwork side). Occasionally plans call for a trapezoidal rib form liner pattern that is not available in a. This accelerates the construction process and minimizes costs. Total cost depends on depth of texture, size and weight of units, and extent of re q u i r ed fabri c a t i o n. As the 2023/2024 school year draws near, parents are looking at a bigger school supplies bill than ever before. Formliners create textured concrete, saving time, labor and material by providing structural and architectural functions in a single medium. High quality concrete panels with less labor cost. Web this is based on a cost of $8 to $16 per square foot for form liner material. Web for over 40 years the fitzgerald formliners team has been developing and manufacturing the most technically advanced form liners. It can also reduce labor costs by eliminating the step of fastening the liner to the form or backerboard every few inches.

[1] form liners come in many different shapes and designs, and can produce a variety of different results on concrete. This accelerates the construction process and minimizes costs. Web custom rock form liner enhances the face of any concrete structure, creating stunning exteriors at a fraction of the cost of natural materials or manufactured facades while maintaining the integrity of your design and producing the exact look you expect. Rustication strip rustication strips are either wood or plastic to attach to form face to produce a groove or rustication in the concrete. Wood grain, stone, brick, and a wide variety of ribbed and other textures make our formliners the best choice. Formliners can be fabricated specifically for your custom concrete form liner patterns and their subsequent decorative concrete formliners. Contact a spec formliners, inc. We highly recommend specrelease, specifically formulated to be used with our form liners. No sacking • no patching no grinding read more about fitzlok. Web formliners can be reinforced with wood or other suitable materials as specified or custom form panels or architectural concrete.

We have the formliner for your design! Polystyrene or polypropylene foam styrofoam can be used in formed concrete as a block out to create various patterns or even logos. Web american formliners pricing guide view, download or print the pdf here… american formliners price list (pdf) Download the brochure 1 1 2 2 3 3 4 4 1 fasten formliner to form using mechanical fasteners, adhesive, or tapes. Ensure the correct side of the liner is facing formwork (sika formliners have a tag indicating the formwork side). Web this is based on a cost of $8 to $16 per square foot for form liner material. No sacking • no patching no grinding download fitzlok® brochure fitzgerald formliners leads the way with a new generation of formliners. Form liners line the inside of your form system. (10 sheets or less) each order is packaged in a protective crate weighing 125 lbs. To put it simply, a form liner or form liner is a rubber (urethane) or plastic mold with a pattern that mimics textures like rock, wood, brick, and any other desired pattern;

Form liner Alchetron, The Free Social Encyclopedia

Web what form release do you recommend for use with the form liners? Polystyrene or polypropylene foam styrofoam can be used in formed concrete as a block out to create various patterns or even logos. Our dedication to our customers, outstanding quality and extensive experience has made us the first choice of specifiers of decorative architectural concrete. Total cost depends.

Form Liners

Wood grain, stone, brick, and a wide variety of ribbed and other textures make our formliners the best choice. Formliners create textured concrete, saving time, labor and material by providing structural and architectural functions in a single medium. Their unique interlocking system provides the ideal solution for projects where seamless finishes are required. It can also reduce labor costs by.

How Much Does a Spray In Bedliner Cost LineX Cost & Rhino Liner Cost

This accelerates the construction process and minimizes costs. Web symons enhance concrete appearance with formliner textures formliners create textured concrete, saving time, labor and material by providing structural and architectural functions in a single medium. This accelerates the construction process and minimizes costs. [1] form liners come in many different shapes and designs, and can produce a variety of different.

National Precast Concrete Association Australia Form Liners

Web while a liner may cost $22 to $24 a square foot plus $12 a square foot for framework, this system costs about $22 a square foot total. Web symons enhance concrete appearance with formliner textures formliners create textured concrete, saving time, labor and material by providing structural and architectural functions in a single medium. Web plastic form liners cost.

Form Liners

Web while a liner may cost $22 to $24 a square foot plus $12 a square foot for framework, this system costs about $22 a square foot total. Contact a spec formliners, inc. Polystyrene or polypropylene foam styrofoam can be used in formed concrete as a block out to create various patterns or even logos. Formliners can be fabricated specifically.

Form Liner Português de partilha de imagens imagens

To put it simply, a form liner or form liner is a rubber (urethane) or plastic mold with a pattern that mimics textures like rock, wood, brick, and any other desired pattern; This accelerates the construction process and minimizes costs. The use of form liners often results in more attractive walls for highways, neighborhoods, beaches and parks. Formliners create textured.

Form Liner Fans Share Images

Web custom rock form liner enhances the face of any concrete structure, creating stunning exteriors at a fraction of the cost of natural materials or manufactured facades while maintaining the integrity of your design and producing the exact look you expect. Web plastic form liners cost from $1.50 to about $7.00 per square foot, depending on the type of plastic.

Form Liners

Web formliners can be reinforced with wood or other suitable materials as specified or custom form panels or architectural concrete. Their unique interlocking system provides the ideal solution for projects where seamless finishes are required. Web american formliners pricing guide view, download or print the pdf here… american formliners price list (pdf) No sacking • no patching no grinding read.

Why choose polyurethane form liners? » Top Elastomeric Concrete Form

It can also reduce labor costs by eliminating the step of fastening the liner to the form or backerboard every few inches. You pour concrete like you normally would and let it set. Their unique interlocking system provides the ideal solution for projects where seamless finishes are required. We have the formliner for your design! The use of form liners.

Stamping Tools and Form Liners Increte Euclid Chemical

Web custom rock form liner enhances the face of any concrete structure, creating stunning exteriors at a fraction of the cost of natural materials or manufactured facades while maintaining the integrity of your design and producing the exact look you expect. This accelerates the construction process and minimizes costs. To put it simply, a form liner or form liner is.

High Quality Concrete Panels With Less Labor Cost.

(10 sheets or less) each order is packaged in a protective crate weighing 125 lbs. This accelerates the construction process and minimizes costs. Web what are form liners? For a custom liner, the price of pre p a r ing the mold must be added.

Web Packaging Fee Of $200 For Any Order Of Less Than 400 Sq.

Web plastic form liners cost from $1.50 to about $7.00 per square foot, depending on the type of plastic and the relief. Contact a spec formliners, inc. It can also reduce labor costs by eliminating the step of fastening the liner to the form or backerboard every few inches. Web custom rock form liner enhances the face of any concrete structure, creating stunning exteriors at a fraction of the cost of natural materials or manufactured facades while maintaining the integrity of your design and producing the exact look you expect.

Our Dedication To Our Customers, Outstanding Quality And Extensive Experience Has Made Us The First Choice Of Specifiers Of Decorative Architectural Concrete.

To put it simply, a form liner or form liner is a rubber (urethane) or plastic mold with a pattern that mimics textures like rock, wood, brick, and any other desired pattern; Web for over 40 years the fitzgerald formliners team has been developing and manufacturing the most technically advanced form liners. High quality concrete panels with less labor cost. No sacking • no patching no grinding download fitzlok® brochure fitzgerald formliners leads the way with a new generation of formliners.

Download The Brochure 1 1 2 2 3 3 4 4 1 Fasten Formliner To Form Using Mechanical Fasteners, Adhesive, Or Tapes.

Polystyrene or polypropylene foam styrofoam can be used in formed concrete as a block out to create various patterns or even logos. Web symons enhance concrete appearance with formliner textures formliners create textured concrete, saving time, labor and material by providing structural and architectural functions in a single medium. Total cost depends on depth of texture, size and weight of units, and extent of re q u i r ed fabri c a t i o n. Web american formliners pricing guide view, download or print the pdf here… american formliners price list (pdf)