Calendering Definition

Calendering Definition - Web calendering can be used to improve the pore opening rigidity of your wire mesh, resulting in more precise performance. The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web. Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. Web this chapter contains sections titled: Web calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure and a suitable degree of dampness. When carried out on a paper machine, it is called. In most cases the end products of the calendering processes are either sheets, films, or. A machine in which paper or cloth is glazed or smoothed by passing between rollers. Calendering is a finishing process used on cloth and fabrics. A machine that smooths or glazes paper or cloth by pressing it between plates or passing it through rollers.

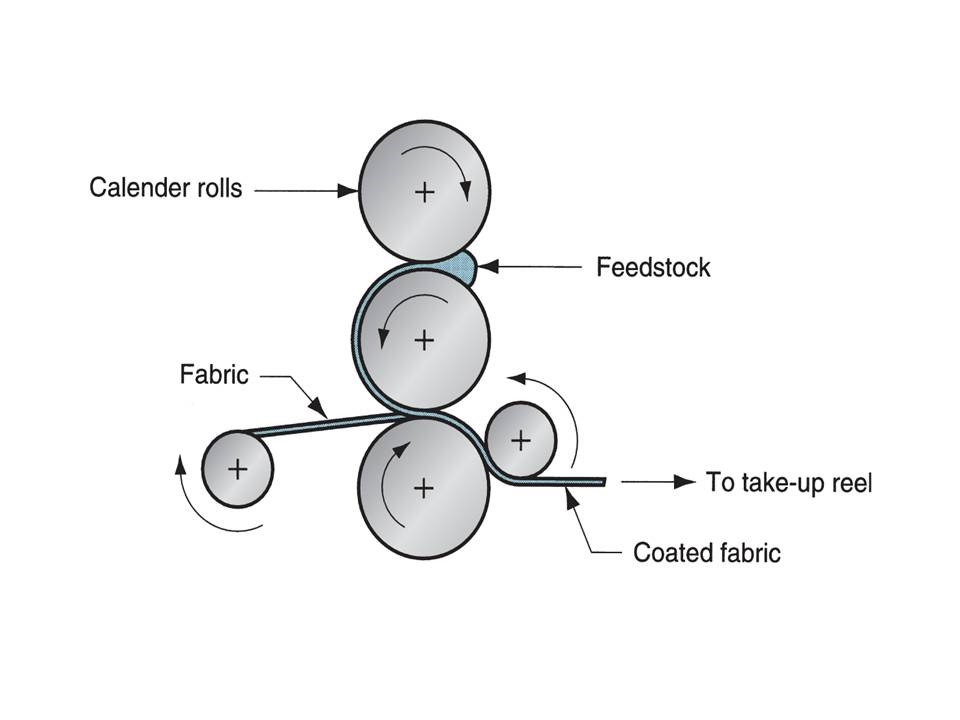

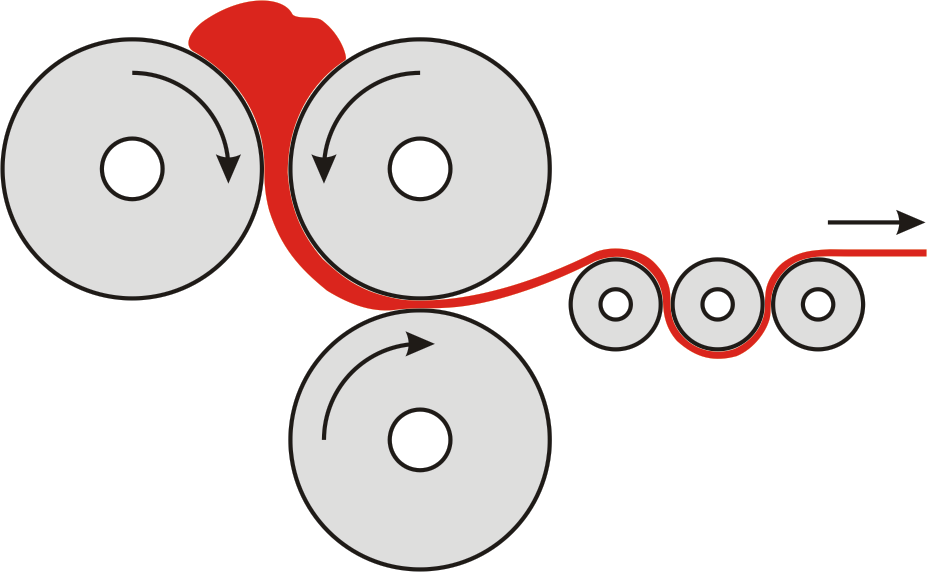

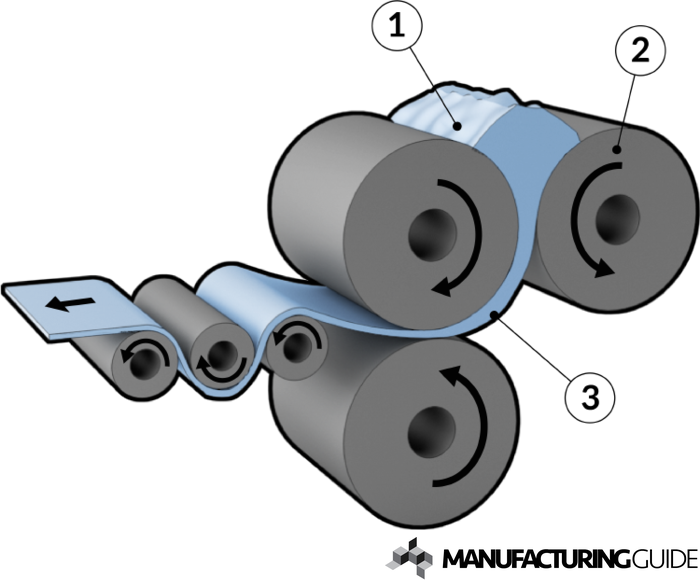

A machine that smooths or glazes paper or cloth by pressing it between plates or passing it through rollers. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Wire mesh can also be calendered to. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. In most cases the end products of the calendering processes are either sheets, films, or. Calendering is a finishing process used on cloth and fabrics. Web film and sheet can, in principle, be made by calendering or by extrusion. Web calendering means the deformation of paper or board under pressure and temperature; A machine in which paper or cloth is glazed or smoothed by passing between rollers.

Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Web calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure and a suitable degree of dampness. With textiles, fabric is passed under rollers at high temperatures and pressures. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Objective and general description of the calendering process. Calendering is a finishing process used on cloth and fabrics. Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. No matter you want a smooth,. The final operation on a papermaking machine, performed to impart to paper a desired finish and to increase the surface smoothness of a paper web. In most cases the end products of the calendering processes are either sheets, films, or.

PPT CALENDERING PROCESS PowerPoint Presentation, free download ID

When carried out on a paper machine, it is called. The rollers are typically made of steel or. Web this chapter contains sections titled: With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web calendering can be used to improve the pore opening rigidity of your wire mesh, resulting in more precise performance.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING

Web calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure and a suitable degree of dampness. Factors that govern the advantages and disadvantages of each process can interact in a. Web this chapter contains sections titled: Web calendering is a textile finishing process that involves passing fabric between two or more heavy.

10 Facts About Calendering in Textile! Textile Property

With textiles, fabric is passed between calender rollers at high temperatures and pressures. The surfaces of the nipforming rolls. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its. Calendering is used on fabrics such as moire to produce its.

6 Types of Calendering Process in Textile ! Textile Property

A calender is employed, usually to smooth, coat, or thin a material. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web this chapter contains sections titled: Web calender in.

Calendering Process Basics Knowing Its Principles And Application

A calender is employed, usually to smooth, coat, or thin a material. Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering. A machine that smooths or glazes paper or cloth by pressing it between plates or passing it through rollers. With textiles, fabric is passed between calender rollers at high temperatures and pressures..

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

When carried out on a paper machine, it is called. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Wire mesh can also be calendered to. Web this chapter contains sections titled: Factors that govern the advantages and disadvantages of each.

Belt & Ply Calendering ProportionAir

Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. It is basically an embossing process. Wire mesh can also be calendered to. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Factors that govern the.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING PROCESS

Calendering is a finishing process used on cloth and fabrics. In most cases the end products of the calendering processes are either sheets, films, or. Web calendering means the deformation of paper or board under pressure and temperature; The rollers are typically made of steel or. No matter you want a smooth,.

Calendering Wire Mesh Definition, Process, and Benefits

No matter you want a smooth,. A calender is employed, usually to smooth, coat, or thin a material. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. It is basically an embossing process. With textiles, fabric is passed under rollers at.

Calendering Definition Nadia Adelina

In most cases the end products of the calendering processes are either sheets, films, or. Web calender in british english. Wire mesh can also be calendered to. Web this chapter contains sections titled: Web calendering can be used to improve the pore opening rigidity of your wire mesh, resulting in more precise performance.

Objective And General Description Of The Calendering Process.

Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. The surfaces of the nipforming rolls. Web this chapter contains sections titled: Web textiles have several calendering processes, including uniform calendaring, chasing, glazed calendering, embossing, and friction calendering.

A Machine That Smooths Or Glazes Paper Or Cloth By Pressing It Between Plates Or Passing It Through Rollers.

Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. In most cases the end products of the calendering processes are either sheets, films, or. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single continuous sheet through a number of pairs of heated.

Factors That Govern The Advantages And Disadvantages Of Each Process Can Interact In A.

Web film and sheet can, in principle, be made by calendering or by extrusion. The rollers are typically made of steel or. Web calendering can be used to improve the pore opening rigidity of your wire mesh, resulting in more precise performance. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its.

Web Calendering, Shown In Figure 2, Is A Unit Operation Which Compresses The Paper Web Between One Or More Rolling Nips.

Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Web calendering means the deformation of paper or board under pressure and temperature; Web calender in british english. Web the meaning of calender is to press (cloth, rubber, paper, etc.) between rollers or plates in order to smooth and glaze or to thin into sheets.